Tips and Tricks

Aperture versus shutter and exposure

Environment illumination provided as standard in an

office or in a production hall is almost sufficient for most

black-and-white video high-speed camera systems. They have

sensitivities somewhere between about several hundred and several

thousand ASA at nominal frame rate depending on amplification.

Color versions usually show about 25% of that only.

The special features in comparison to standard imaging mainly

derive from the usually short exposures and the working close to

limits - physical and technical ones.

Otherwise obviously the usual photographic rules, restrictions

and, of course, possibilities are valid.

Tips for shooting

Illumination, aperture (f-stop) and dynamic

Evidently it is valid: everything counts in large amounts.

The more light is offered the more the aperture can be closed, i.e.

a higher f-stop number can be set, enhancing the depth of field. At

f-8 or higher it is well done, but 5.6 is sufficient enough.

Usually there is never too much light - it is possible to shoot the

glowing filament of a 500 W tungsten bulb, the hot spot during

laser welding or an electric discharge. (Caution, directly viewing

in the laser beam is then too much of a good thing.) Only the

brightness dynamic of the camera is problematic. That is just valid

for all electronic cameras. Good to notice when making a photo

looking outside a window deep from the room. (Therefore in

interviews in office rooms one prefers to shut the curtains or

jalousie. Besides then the spotlights are not so intensively

reflected. Until HDRI (high dynamic range image) is widely spread

some time will pass.) The usual 8 to 12 bit or 256 to 2 048

brightness levels, should be optimal used, even if 64 gray tones (6

bit) provide a sufficient quality. If one wants to image the less

illuminated environment, one will have to light it up. Comparable

to the additional (background) light-up flash in photography.

Just to mention, if it is too bright at all, (neutral density,

short: ND; i.e. neutral, colorless) gray filters will offer help.

Or selective filters, which e.g. dim the wavelength of a welding

laser, but not those of the weld deposit. Many lenses provide

threads for that reason.

Practice-oriented example: if one wants to image the sparkles of a

cigarette lighter together with the holding hand, about

1 000 W will be necessary (see sample 2 with and 3

without lighting up in [SloMo Clips]).

By the way: the dynamic range is often given in units of decibel

[dB]. The connection to bits and bytes gets clearer with the

following formulas:

x [dB] = 20 × log y and y = 10x/20, resp.

In which x represents the value in dB and y the number of

sensitivity steps.

Thus 8 bit (= 28 = 256) make so 20 × log 256 =

48 dB, while 60 dB stand for 1060/20 =

1 000, so for about 10 bit (210 = 1 024) dynamic

range. Thus 12 bit would be about 72 dB. These are typical values.

As technical expression here the term signal to noise ratio is to mention. It indicates how much stronger the useful signal »exposed image« is compared to parasitic effects - not in the latest charges of a pixel (in real a photocell; ~»solar cell«) are even spontaneously and arbitrarily generated without any illumination but caused thermally only. And the term full well capacity indicating how much charge a photocell can generate at all until saturation takes place, thus more incident light does not generate further charge carriers. Here large area pixel show their advantage concerning dynamic.

Click for flicker illumination effect: [SloMo Freq.]

More about light -

Photo hf:

Photo

Professionals use at least halogen spots in studio quality

(defined color temperature ...), cool beam reflectors (with

reduced IR spectrum), or even HMI spots (daylight spectrum) and DC

illumination devices (rectified) to avoid the jitter of the

50 Hertz or 60 Hertz, resp. (1 Hz (Hertz) = 1/sec), power

supply frequency.

There are obviously lamps switching on and off during operation

and one usually does not take notice of it. Even light emitting

diodes (LED) can flicker, partly unintended due to a not sufficient

enough stabilized DC power supply. But partly also intended - the

maximum current, and thus the (momentary) brightness of the LEDs in

flash mode, is namely allowed to exceed that of continuous

operation by far. (Suitably synchronized they are appreciated

because of their lack of radiate off heat.)

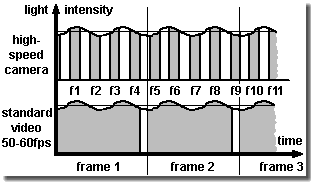

A sequence mainly illuminated by common fluorescent tubes therefore may

show distinct pumping brightness, see the figure on the left

and for details see [SloMo Freq.]. The

effect is also known from flickering slow motion replays on TV broadcasts.

(Obviously there were some reasons for the good old light

bulb. ;-)

Due to the different color temperatures of light sources, e.g. the

tungsten filaments of halogen lights shine with longer wave-length

or warmer (i.e. more yellow,reddish) than daylight, electronic

cameras offer a so-called white balance feature. Then white will

become pure white again.

And caution: a halogen spotlight with a nominal power of

1 000 W heats with about 900 W. This might be

sufficient enough to melt plastics within a distance less than

1 m after a while!

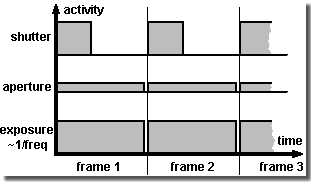

Exposure and aperture (f-stop)

Function of shutter and aperture (f-stop)

Liquid Crystal shutters using Displaytech's FLC types.

Designed for external or internal mount.

Supply and control by the camera electronics.

Exposure, better the maximum time of exposure, of most high-speed cameras, is nearly 1/frame rate. With e.g. 1 000 frames per second, thus the time of exposure cannot exceed 1/1000 second. The sensor is integrating (= gathering) over the incoming illumination during this span of time.

In fact the sensor is ready for shooting during the whole time

of exposure of one single frame. The gray areas under the curves in

the upper image on the right give a measure for it. The narrow gap

between the frames is the read-out and/or initiation time of the

sensor, duration in the range of some microseconds or even

less.

Closing the aperture of the lens (f-stop) reduces the amount of

incident light global for all frames. The bigger the f-stop number

the smaller the iris aperture gets and the less light reaches the

sensor.

A shutter reduces the incident light, too, but by repeatedly

reducing the (fixed) time of exposure of each single frame.

Technical spoken it changes the duty cycle and reduces the

effective time for one single shot or frame.

While the f-stop in general limits the light intensity for

exposure the shutter is mainly used in order to reduce distortion

caused by motion (motion blur). Because if the object is moving

during the time of exposure with more than 10% of its size, this

will be bothering usually. (In still photography one accepts just

up to 3% if ever.)

There are different possibilities for reducing motion blur:

-

Increasing the frame rate (may cause a decrease of resolution due to camera possibilities and a demand for more light)

-

Use of a stroboscope (where the background illumination must not be too bright and the area illuminated by the stroboscope is limited)

-

Use of an optional shutter, e.g. a liquid crystal shutter (LC shutter), which permits exposure down to about 1/10 000 sec, but causes the loss of two aperture steps even totally opened (transmission typically about 30%).

Many up-to-date systems offer as standard a more than ten times

faster electronic shutter in their chip design and therefore do not

need an additional LC shutter. Exposure times of microseconds and

less are not technical problems, but export topics addressed by

dual use restrictions (military use and proliferation).

For those, who want or need more - in this case shorter exposure

times - a Kerr cell or a Pockels cell, or possibly a microchannel

plate (MCP) can help. Of course, there are mechanical shutters and

choppers in the shape of slit or hole wheels, too.

Annotation: in contrast to the mentioned above global shutter (or

snap-shot shutter, freeze-frame shutter) simultaneously operating

on the whole sensor, there is also a line by line operating rolling or

slit shutter. Concerning movement analyzing one should prefer

cameras with the first one, because the line scanning of the sensor

does not guarantee to take the resulting frame at a defined moment

and according artifacts can occur.

Changing the shutter time one can vary the illumination, of

course, if one is not able or does not want to adjust the aperture

(f-stop) ring. The latest concerns more the artistic approach,

because the depth of field depends on the aperture. It increases

with the f-stop number. Who ever may need it...

Depth of field (or depth of focus)

Expression for the distance region where objects appear

sharp on the image. The reason why it is not just a simple point

like the inscription on the distance ring (focus) seems to claim,

is that within a tolerance area the film, the sensor or one's eyes

do not show resolution enough. When a point is displayed within the

so-called circle of confusion (about 0.01 mm to 0.025 mm

diameter with common sensor formats and 0.033 mm with

35 mm format cameras), one will not perceive the blur at

all.

The position and expansion is mainly dependent on the aperture:

small aperture (= higher f-stop) number - large depth of field.

Where it is larger behind the calculated position of focal distance

than in front of it.

Depth of field increases with shorter focal length and greater

distance to object. Larger film/sensor format exact larger

pixels, resp., however, permit to decrease it. (Due to crop factor

sensor shrinking increases depth of field by force.)

There is a rather bulky formula, see distance and focal

length calculator [SloMo f = ∞].

Anyway depth of field is a no-word in high-speed imaging in industrial

environment (mostly the aperture of the »Dark-o-matic« is just opened

like a barn door. ;-).

Using the so-called hyperfocal distance h the region starting at

h/2 to infinity appears in focus. It is also called fix focus

setting or near adjustment and is especially used with simple

cameras.

Cheap lenses, especially for surveillance cameras, often do not

even offer a focus ring. They are focused by the aperture only.

Here the electronic amplification (gain) of the cameras has to

provide the required brightness.

Field of view and lens

Endeavor to do a good job: image the interesting scene

as screen filling as possible. With C-Mount it is not too tricky to

use spacers (extension tubes in a set for less than

€/$ 50.-) and a fixed focus lens or an additional short

distance lens for covering the entire screen with an object of

5 mm (= 1/5 inch) in diameter. Do not choose a wide-angle lens

with a focal length smaller than 6.5 mm (concerning C-Mount

2/3 inch format) for applications using automatic image processing

(e.g. with object tracking), otherwise distortion would reach a

level not to be tolerated. All lenses and equipment suitable for

the according mount can be used, even filters, macro, zoom and

fish-eye lenses and with appropriate adapters photo lenses,

bellows, microscopes, endoscopes, boroscopes, fiber optics, image

enhancers (night goggles) ... But pay attention to the fact the

more complicate the optics are the more illumination is often

necessary.

Professional photo stores offer adapters to fit common lens

mounts, e.g. C-mount to Nikon bayonet (Nikon F). Some high-speed

cameras (like many professional photo cameras, too) additionally

allow - due to a mounting plate/reference plane - the choice of a wide

range of (customer) specific adapters including popular ones like

Nikon F or C-Mount and others e.g. PL, Kinoptik or Stalex

(M42).

Click for focal length calculator [SloMo f = ∞]

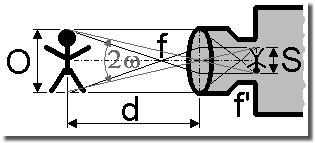

Actually the focal length inscription on a lens is

the focal length at the image side if imaging an object in

infinite distance with a wave-length of 546 nanometers. Then the

image will appear in the focal point located at the image side of the

lens.

The definition according to DIN 4521 standard is:

f' = limω-->0 (y'/tan ω)

With the half field angle ω and the half

image diagonal y'.

(Subsequently the field angle is simplified - not the optical

path, but the image position is of interest - to be the angle of

view due to format filling setup and f' and f are just taken as the

focal length inscription of the lens.)

The rule of thumb for a rough calculation of the focal length for a format or a sensor filling image S is

focal length = distance to object / (1 + object size / image size); [all values in mm]

And the estimate of the necessary distance at given focal length is

distance to object = focal length × (1 + object size / image size); [all values in mm]

The angular field of view FOV = 2ω (identical with 2ω', see the figure above) is given by

FOV = 2 × arctan (1/2 × image size / focal length)

The magnification M derives from the imaging through the lens onto the sensor and the display of the image on the monitor or other media

M = focal length / (distance to object - focal length) × diagonal of monitor / diagonal of sensor; [all values in mm]

One must pay attention to the restrictions of standard lenses.

In a distance less than 0.3 m (approx. 1 foot; sometimes even

1 m, approx. 3 feet) to the object they cannot provide sharp

images. In such cases one needs a spacer (= extension tube), an

additional short distance lens or a micro (-scope) lens, and so

on.

The thickness t of the spacer, which is screwed in between lens

and camera body, is given by

t = image size / object size × focal length; [all values in mm]

in which the relation image size / object size is called imaging scale. But caution, just despite of their simplicity - extension tubes swallow light.

Fine adjustment of flange-back (back focus lens adjustment)

Evidently a wrong adjustment of flange-back derives from

manufacture tolerances, mismatch (incompatibilities of components)

and media brought in the beam area between lens and film or sensor,

resp. And concerning crash-proofed cameras mechanical stability is

above all, even above (too sensitive) adjustment mechanics.

Provided that the suitable adapter is selected using a lens of

fixed focal length one easily receives sharp images by turning the

distance ring (focus). Maybe the distance inscription and the

magnification are slightly wrong then. Usually this does not bother

one further more.

Using a zoom lens, however, one looses the sharpness (i.e. focus)

of the image during zooming process. As a rule it should be steady

and only magnification (and thus the angle of view) should change.

Then the zoom lens is only usable in a restricted manner as vario

lens. One is ought to adjust sharpness simultaneously during

zooming all the time. High-speed cameras, however, are rarely used

for such zoom shots.

Nevertheless, in order to take full advantage of the zoom feature

the flange-back has to be adjusted accurately. Using simple tools

proceed as follows:

-

Open aperture as wide as possible to reduce depth of field (if necessary dim the room illumination, reduce time of exposure, ...)

-

Select an object in a distance of about 3 m to 7 m (this is about 10 feet to 23 feet)

-

Gain a sharp image at maximum zoom (biggest focal length) by turning the distance ring (focus)

-

Gain a sharp image at minimal zoom (smallest focal length) by changing flange-back. (Do not turn the distance ring hereby.)

-

Iterate until you receive sharp images at both zoom positions without re-adjusting

To adjust flange-back camera housings offer either a thread tube

to be moved back and forth - almost standard with C-mount cameras.

Or metal pads (washers) are fed in between lens adapter and camera

body if not even mechanics are integrated in the camera body in

order to change the sensor position. There are also lenses,

especially C-mount ones, with a cylinder housing at the camera

side, which can be shifted. Look for a small depth bold at its

circumference.

The IR switch of high-end lenses does nothing different. It quasi

moves the lens away in order to project the IR images onto the

sensor.

Evaluation and measurement

Eminent: please do not forget you receive a lot of data. A megapixel resolution at 1 000 frames/sec and more just leads to data rates in the Gigabyte/sec range. Thus more than a complete CD-R per second would be filled. Per each camera, mind you. (Here at [SloMo Data] you will find the formula to estimate the data amount.) So do not wonder why the high-speed camera system is rather busy, when downloading, saving and viewing these files. And - it is highly recommended to have a storage/backup concept for the files.

The huge data amounts cause the cameras to be used offline. Thus

they are not immediately used for controlling and they are not

directly integrated in a superior machine control circuit. The

image processing would be just too costly and too slow. One watches

the scene and analyzes afterwards.

(Today slower cameras of the image processing sector - »machine

vision« sensors - can already be equipped with a lot of calculating

power, therefore named smart cameras, allowing them to work like a

sensor only providing a simple good/bad signal for the control unit

- e.g. »Label position on the bottle is all right - Yes/No?« - and

not sending image data for further computing.)

Trajectory evaluation: translation, rotation,

velocity, acceleration and stick-figure animation

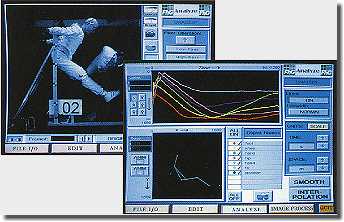

For controlling high-speed cameras even multi-channel systems of

different suppliers special software is available. The evaluation is

carried out either directly visual or using motion analyzing

software packages, so-called motion trackers. See e.g. the

links given in [SloMo Links].

To make it easier for automatic motion tracking by software one

should pay attention to ensure a homogeneous background and, if

possible, to avoid gratings, chessboard pattern or something

similar (like a wallpaper with flowers ;-). Thus reducing the

calculating time and preventing the tracking algorithm getting

stuck with the attractors in the background instead of pursuing

the desired target.

D-Load

If you intend to archive your image files in AVI format,

consider making use of the compression tools Intel Indeo

or DivX saving up to 90% memory capacity without loosing

too much quality. DivX will often provide smaller files, especially

if less movement happens in the scene. In contrast Indeo commends

itself for automatic image processing, because it manipulates

object position in a smaller extent.

AVI files can be processed (i.e. changing frame format, replay

speed ...) with e.g. video editing soft-/freeware. For these

and other tools just have a look here in the download center,

see the button on the left.

Namely one shoots sequences with super slow motion to slow down

fast movement for visual inspection, nevertheless, one should

create some faster replays, e.g. with 25 to 100 frames/sec (of an

original with 1 000 frames/sec), otherwise the impression of

movement is lost. This will become important then if one wants to

show the sequences to some outsiders, who are not so familiar to the

scenery.

Because the high-speed cameras run also with a normal speed of 50

or 60 frames/sec it is also possible to shoot true video clips. And

copied on a USB stick with the same replay speed one can hand out

it to the customer the machine has been built for with the words

»So your machine has been working during the final tests«.

Just generating a sophisticated impression, not only with the high

resolution cameras. Thus the test becomes a advertising movie.

Tricks for system integration

Trigger and synchronization

Easy to understand - to trigger means nothing else, but to

start something caused by a single event. For instance the

recording will be started, when the crash test vehicle hits the

wall. The trigger device is often just a simple closing contact at

the bumper providing a short circuit in the impact moment or a

light barrier. (Often a flash light additionally marks »frame

0«.)

To synchronize means to stabilize the frame rate in a defined

relation and a fixed delay towards a repeatedly happening event

during a period of time. Ideally this is done by a recurring

control signal, which causes a frame to be captured each time. So

using a stroboscope as illumination source one will adjust the

record phase of a camera so that it will be in recording mode, when

the stroboscope flashes. So one equals the frame rate and the flash

rate and adjusts the image capture to ensure the camera is active

during the flash, not that its shutter is just closed, thus it is

able to catch the rather short flash.

Sometimes cameras offer a so-called »strobe« control

signal. It marks the phase of exposure of each frame; during the

cameras is in exposure mode, it is set.

Triggering is not as simple as it seems at all. Because the synchronously operating camera has to react on a sudden asynchronous trigger impulse after all. Therefore a capture gap can easily occur, because the camera has to finish the previous image capture before. Due to possibly already writing in the image ring buffer memory when the trigger impulse comes high-speed cameras often do not show a so-called restart capability like video cameras without image memory can offer. The latter are able to start a new frame almost in time with the trigger. Earlier image data are discarded where necessary.)

If one wants to trigger or synchronize various

devices, one will face the problem of different signal levels,

impulse widths and phase shifts not willing to work

together.

Therefore here on the left side a very simple and cheap circuit,

see [SloMo Trig.] for

explanation, which may be helpful for some adjusting jobs.

(Because not everywhere »Trigger« is labeled, trigger is

really inside. ;-)

Just in multi channel and especially in 3-D measurement applications synchronization between the cameras and their triggering in general becomes extraordinary important.

In frame trigger and external trigger

Engineering and CMOS make it possible. The trigger is released by the frame content as soon as a predefined color change of a certain pixel count surpasses the threshold value in an also predefined region of the (live) image. Elegant, but what to do if it is necessary to react on an electrical trigger signal from outside, but there is no interface available for it - e.g. at the smartphone? Just place a LED into the scene and operate it by the external trigger. That is then the useful trigger region. A small delay may occur. Well, possibly a nice job to measure it?!

Remote control

Exercise: a camera head should be adjusted (scene, aperture, sharpness, shutter, trigger, format ...), but the host PC is in a distance, e.g. in a control room behind a safety door, so that no live image is available near the camera. Or one wants to control the camera system from an extended distance.

The common interfaces (Gigabit Ethernet, etc.) are sufficient

fast enough, but one is often dependent on expensive control

software of the camera manufacturer or a third party

provider. (And WLAN is tricky thing - either the camera is not

equipped with it or one is a little bit scared due to the sensible

data.)

Why you do not just try an inexpensive KVM? A keyboard-video-mouse

extender (or switch) offers an efficient remote control without

interfering with the PC. Even additional driver/software are not

necessary.

The KVM consists of a transmitter and a receiver in the simplest

case connected with a standard Cat 5 UTP Ethernet cable. The

transmitter is plugged to the control host PC instead of keyboard,

mouse and PC monitor. The real peripheral devices are connected to

the receiver. Now one can operate at the receiver as if the host PC

stands beside one's knees. Depending on the chosen

system or transmitting technology, resp., distances of several ten

meters up to some hundred meters and even more are possible.

Meanwhile All Share®, Airplay® or whatever may be a

substitute. Even a WLAN monitor. But do not underestimate the delay

for sending and displaying a frame through air, especially if you

want to use it for triggering by hand. Test it!

Autologon and automatic start

Exercise: a Windows PC with or without Ethernet connection should start alone. In a special case even without connected keyboard, mouse and monitor.

One can bypass the password query using the autologon feature of

Windows. (Attention: after that the password for the system and the

network stands in the registry.) One creates a new user account

without password query or one sets an exiting account

accordingly.

If desired, put the program (or its shortcut) you want to start

automatically in the Autostart folder to be found in the

Start menu programs.

Additionally activating in BIOS »halt on no errors«

causes the PC not to wait on a feed-back of a keyboard or a mouse.

This will make sense if you can operate the system by a remote

control.

Result: the system runs up to the Windows Desktop, and with your

desired program in the Autostart folder, even up to your

application.

Visit the Windows Help if necessary.

Cleaning lenses, sensors and LC shutters

Experts at work - of course, nobody has grasped on the

lens and even less one has left the lens uncovered until a regular

dust hill has gathered on the top. Blow off would not help yet and

one has too often the impression to distribute the dirt only during

a cleaning attempt at all. Not to mention the risk of scratching

the comparatively sensitive anti-reflex coating, when using a dry

duster.

Alcohol (isopropyl) drenched cotton pads, damp cleaning rags

for spectacles or chamois leather with water thinned dishwasher or

window cleaning detergents (and soft wipe paper to remove their

residues!) are much better. The ultimate tool against fingerprints

and dirt on glass, however, is e.g. First Contact Polymer

(substitutes Opticlean Polymer from Dantronix) - not quite cheap,

but final; or just even use the lens hoods instead ;-).

Usually the sensors of video cameras are protected by a sometimes

coated, i.e. with optical layers, glass plate. Especially in still

cameras and black and white configurations, however, the chip can

be plane open. Then caution should be exercised when cleaning due

to the sensitive color pattern film (polymer) or the sensor

surface and its bond wires. It is highly recommended cleaning the

LC shutter, if ever, with much more sensitivity than one is used to

do so with glass surfaces.

When no voltage is supplied to the LC shutter, it may show spots

and blots making it look spoiled. Do not worry, the operating

voltage will erase them all. You can easily check this by operating

it at the camera with low frequency and trying to look through it.

Or by supplying alternating DC voltage (±5 V? see manual!)

to the shutter and looking through it.) Then it completely opens

and completely closes.

Extend the [TOUR] to images, info and technical data of the SpeedCam systems as an example for the features of digital high-speed cameras.