Block Diagram of High-speed Cameras

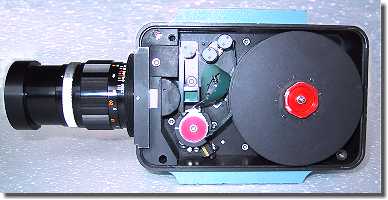

Interior of film and sensor cameras

Stalex film high-speed camera: 3 000 frames/sec

Existing since decades: high-speed camera had their origin in film technique. Here on the right a crash-proofed 16 mm rotating prism camera out of the 1960s.

The Weinberger Stalex projects 3 000 frames/sec on continuously transported 16 mm film (standard 110 m daylight reels). The prism feeds the image according to the moving film in order that it mutates to a freeze frame during time of exposure.

Interior of a rotating prism high-speed camera

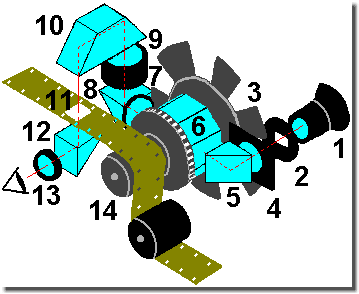

Evinced specs of the Red Lake HYCAM: 10 000 frames/sec on

16 mm film, 48 000 frames/sec in 1/4-format.

To give a rough idea of dimensions - the camera (without lens

equals the size of a bigger briefcase and a weight of several

kilograms.

Rotating prism high-speed camera HYCAM

1) Object lens

2) Field stop (image size limiter)

3) Rotating segment shutter

4) 1st field lens

5) 1st prism

6) 8-plane compensation prism

7) 2nd field lens

8) 2nd prism

9) Intermediate lens

10) U (reverse) prism

11) Image (film used as screen)

12) Prism

13) Ocular (view finder)

14) Synchronized gear drive

Film: 16 mm; glass: lenses and prisms; rotating parts: segment shutter, compensation prism, film transport; mechanics: lens holders, guiding rollers

Function (analog)

Exact rotation of segment shutter and compensation prism

and also transport of film are synchronized. Thus the shutter

defines the time of exposure of each frame, while the compensation

prism feeds the image according to the continuously spooled film to

avoid motion blur/defocusing. Because this feeding is not always

perfect concerning time and especially location the sequences may

show a certain jitter from frame to frame.

The film is used as screen for the ocular, so one gets some kind

of SLR (single-lens reflection) feeling without parallax

effects.

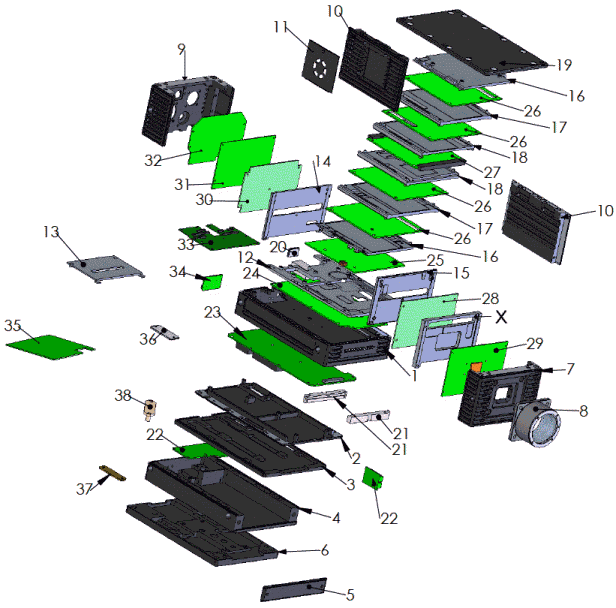

Interior of a digital high-speed camera

Exploded assembly drawing of a crash-proofed digital

high-speed camera Weinberger SpeedCam Visario G3 of 2007 for comparison. Technical

data: 1 000 frames/sec at 1536 x 1024 pixel, with reduction of

resolution 100 000 frames/sec.

The camera (without lens, but with both optional battery modules)

has about the size of a bigger brick and weight of some kilograms.

Crash-proofed digital high-speed camera SpeedCam Visario g3,

exploded assembly drawing

1) PC well

2) Cool blade power supply

3) Battery flange

4) Battery shelf

5) Battery clap

6) Adapter plate

7) Front

8) Lens adapter

9) Rear

10) Side wall

11) Fan cage

12) Computer cooling plate

13) Video cooling plate

14) Link cooling plate

15) A/D converter cooling plate

16) DRAM cooling plate 1

17) DRAM cooling plate 2

18) Controller cooling plate

19) Shell cover

20) Fiber-optic cover

21) Stiffener

22) Battery connection

23) Power supply

24) Linux computer

25) Fan controller

26) Memory module

27) Camera controller

28) A/D converter module

29) Sensor module

(CMOS sensor in orange)

30) Link module

31) Interface module

32) Connector module

33) Signal router module

34) Power supply plug

35) Video module

36) Closing plate charger

37) Closing plate power supply

38) Stiffener charger module

X) Sensor cooling plate

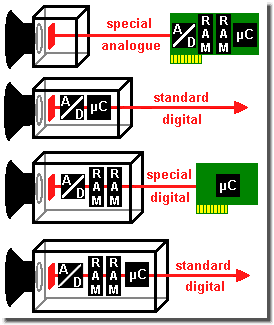

Function (digital)

Digital high-speed camera concepts

Each cooling plate is used to stiffen the printed circuit

boards, too. The fans are only necessary under intensive

temperature load, e.g. under strong irradiation from the

environment.

Optional harddisk and video interface make the camera a full-value

camcorder. The integrated Linux computer presents additionally

options. Control takes place via Gigabit Ethernet and firm control

signals. This functionality is typical for high-speed cameras out

of the upper performance segment.

Meanwhile fast internal and possibly exchangeable mass storage

devices (e.g. SSD) complement the interfaces for image data

transfer.

Legend to the figure on the right: RAM = image

memory; µC = microcontroller or processor; A/D = analog to

digital conversion (often already integrated in the sensor)

The green card should show a PC card, the red line connection

possibilities (image and control data).

The standard connection can be e.g. (Gigabit) Ethernet or

FireWire.